If you are owner of a new watch brand, you are very likely to hear this when you are talking to your watch manufacturer. You asked: “How long does it take to make a custom sample for my brand?” And they replied without second thought: “60 days!” You were taken aback and said to yourself, “Wow, it’s 2 months! Why does it take so long?” This article will offer an explanation for that.

Watch making companies don’t and can’t work alone. A watch has so many components that a single factory, no matter how big it is, has no means to produce all the watch parts and do all the procedures alone. Your watchmaker is a watch assembling factory at most. They outsource the watch parts to sub-contractors (strap factories, dial factories, hands factories, casing factories, etc) and finally do the assembling in house. This is an industry-wide reality. It’s true for big brands too.

Coordination takes time. The watch casing (housing) is the most time-consuming part to make. It is a good thing if stock is available, but most of the time the manufacturer has to start from scratch when customization is required. Die cast molds have to be made first if the casing design is completely new. This usually takes 30 days or more. Other casing part, such as glass, caseback, sealing ring and crown, will take another 20 days. Customized texts on caseback and case color variations will require an extra 5-10 days. Therefore, casing production often takes 55-60 days when no stock is available.

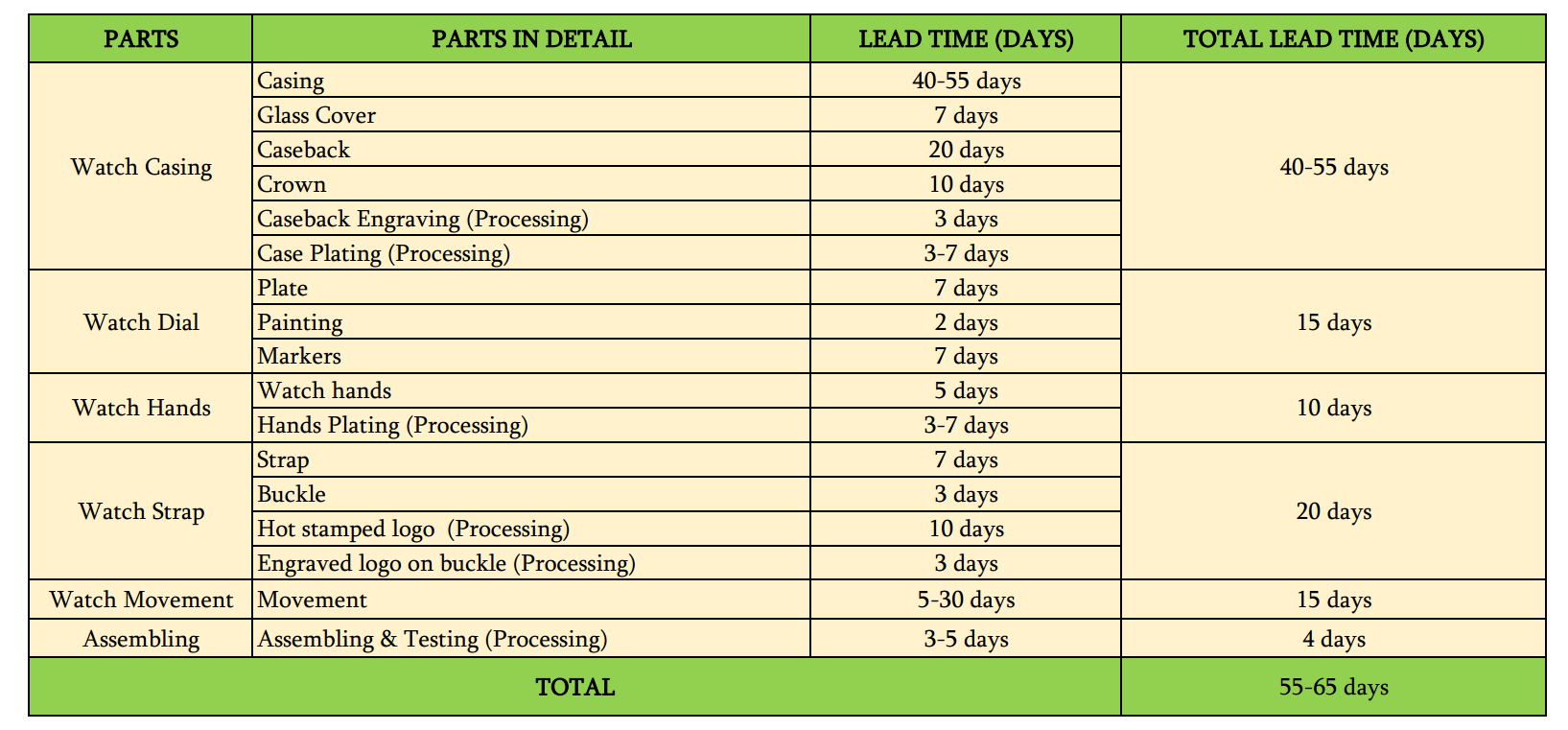

To better explain the lead time for each watch part, a table is provided below.

As can be seen from the table above, some parts take a short time to produce while others long. The total lead time is simply an average. However, if you are flexible with the cases, then there certainly are solutions to shorten the sample project time. It takes time to make your own custom watch, so please be patient!

If you are thinking about building your own watch brand, please feel free to contact Ascend Team for assistance.